YTRON-ZC Powder Disperser – Efficient Powder Dispersion with Minimal Energy Consumption

Did you know that YTRON machines require significantly less power than many competitors? Our inline powder dispersers, in particular, operate with less than half the usual power consumption – without compromising performance.

Why is the YTRON-ZC Powder Disperser so efficient?

Our unique technology is the key: YTRON dispersers deliver optimal dry material distribution without providing maximum pumping power. In contrast, inline dispersers with integrated shear pumps often struggle with powder incorporation, particularly at higher viscosities.

YTRON helps you save time and energy every hour of production – day in, day out. The payoff is clear.

Optimized Powder Wetting for Best Results

Powder intake is driven by strong vacuum in the ZC reactor, incorporating dry materials which are then dispersed and wetted immediately upon contact with the liquid phase. This process is completed before the powder is fully hydrated.

Thanks to the extremely short shear exposure, the product is treated very gently. Even shear-sensitive thickeners and gelling agents achieve maximum viscosity in a single pass.

Rely on the YTRON-ZC powder disperser for top efficiency, minimal energy use, and exceptional dispersion results!

Highlights of the YTRON-ZC Powder Dissolver

- Rotor/Stator Technology: Tool selection tailored individually to the application

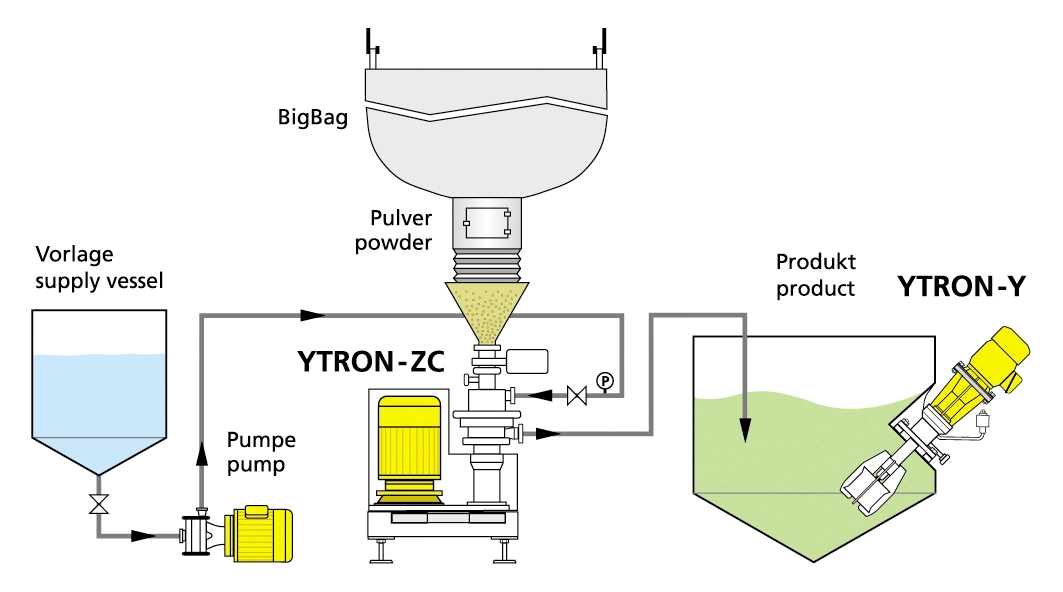

- Flexible Feeding: Adaptable to requirements (hopper, suction lance, big-bag systems, bag dip station, silo, and more)

- Hygienic Design: All versions are CIP (Clean in Place) compatible; SIP (Sterilization in Place) available on request, ensuring maximum product safety

- High-Quality Materials: Stainless steel, special alloys, hardening, etc.

- Explosion-Proof Version: Available for ATEX Zones 1 and 21

Top Benefits of the YTRON-ZC

- Efficient Powder Wetting: Even hard-to-wet powders are fully dispersed in a single pass.

- Optimal Viscosity Control: Targeted shear creates the STRETCHING® effect, increasing viscosity through a special mechanism.

- Air-Free Processing: Minimal air inclusion prevents foaming and oxidation of the product.

- Maximum Efficiency: Reduced process time thanks to rapid and intensive powder dispersion.

- Cost Savings: Lower material usage due to highly efficient powder processing.

- Fast Further Processing: Perfect dispersion with minimal soaking time.

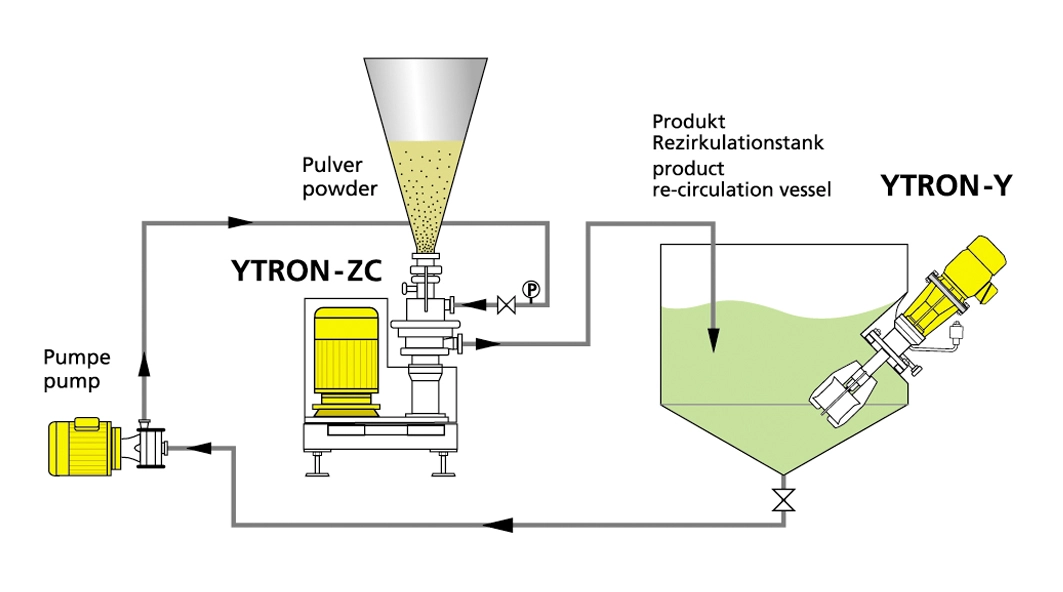

The YTRON-ZC powder disperser separates dispersing and pumping power, making the dispersion process both reproducible and economical. Only a small portion of the energy input is used for pumping – the majority is devoted to intensive dispersion and wetting of the dry materials in the liquid phase. Combined with the optimal pump for the liquid phase, this achieves high efficiency. Centrifugal pumps are used for low viscosities, while positive displacement pumps are required for higher viscosities.

When processing high-viscous liquids, up to 80% of energy can be saved compared to conventional methods. The dispersion process delivers reproducible results in a single pass. The product is homogenously and uniformly dispersed without requiring additional flow to bypass the dispersing tools.

Typical application examples for the YTRON-ZC

The YTRON-ZC disperser is ideal for processing difficult-to-disperse substances such as thickeners, binders, stabilizers, and gelling agents. These include, among others:

In a special configuration, the YTRON-ZC is also suitable for high dry matter content in a single pass or under recirculation – for example, for silicates and binders in high-viscosity liquids such as sugar syrup or chocolate mass.

Special Feature: For most products, a single pass through the YTRON-ZC is sufficient to achieve an agglomerate-free product. This makes the process particularly suitable for shear-sensitive materials. Even with multiple passes, the shear effect remains reproducible.

YTRON-ContiCone – Precise Inline Powder Dispersion with High Control Accuracy

The YTRON-ContiCone disperser is an advanced development of the proven YTRON-ZC powder disperser, enabling the immediate dispersion of a defined amount of powder with controlled liquid flow.

The ContiCone technology offers high control accuracy and allows continuous inline dispersion at concentrations of over 50% (depends on product). Its closed design minimizes dust in the production area, ensuring clean and efficient processing. This technology can be combined with all common powder dosing systems and is suitable for almost all low-viscous liquids.

Typical applications include the food industry, cosmetics, and chemical processes where precise and uniform dispersion is required.

YTRON-ZC Powder Feeding Table – Efficient Dispersion Without Agglomerates

The YTRON-ZC disperser with powder feeding table simplifies the addition of dry materials thanks to its low construction height. Bags can be placed on the table during addition, providing an operator-friendly and ergonomic handling.

The compact design is available in various configurations, making it ideal for the food and chemical industries.

YTRON-ZC ViscoTron – Efficient Dispersion at High Viscosities

The YTRON-ZC ViscoTron was specifically developed for applications with high viscosity and high dry matter content. By combining the proven YTRON-ZC technology with a positive displacement pump at the inlet and outlet each, a stable process is achieved even at high viscosity.

Due to the vacuum generated at the powder inlet, the YTRON-ZC ViscoTron can be easily fed using a suction lance – ideal for efficient and low-dust processing.

For more information, please refer to our brochure

In our brochure, you’ll find detailed technical information about the YTRON-ZC disperser along with clear application examples. Discover how our machines perform in real-world scenarios, what makes them technically outstanding, and how they can benefit your production.

BROCHURE DOWNLOAD YTRON-CONtiCone