YTRON VacuPlant®

- YTRON VacuPlant® is a universally applicable system for mixing and dispersion of powders and liquids

- Using vacuum to draw in powder, the VacuPlant will disperse, dissolve, deaerate and emulsify with ability to heat and cool as required.

- Optimised process configuration

- We work in partnership with our customers to develop tailor-made process solutions

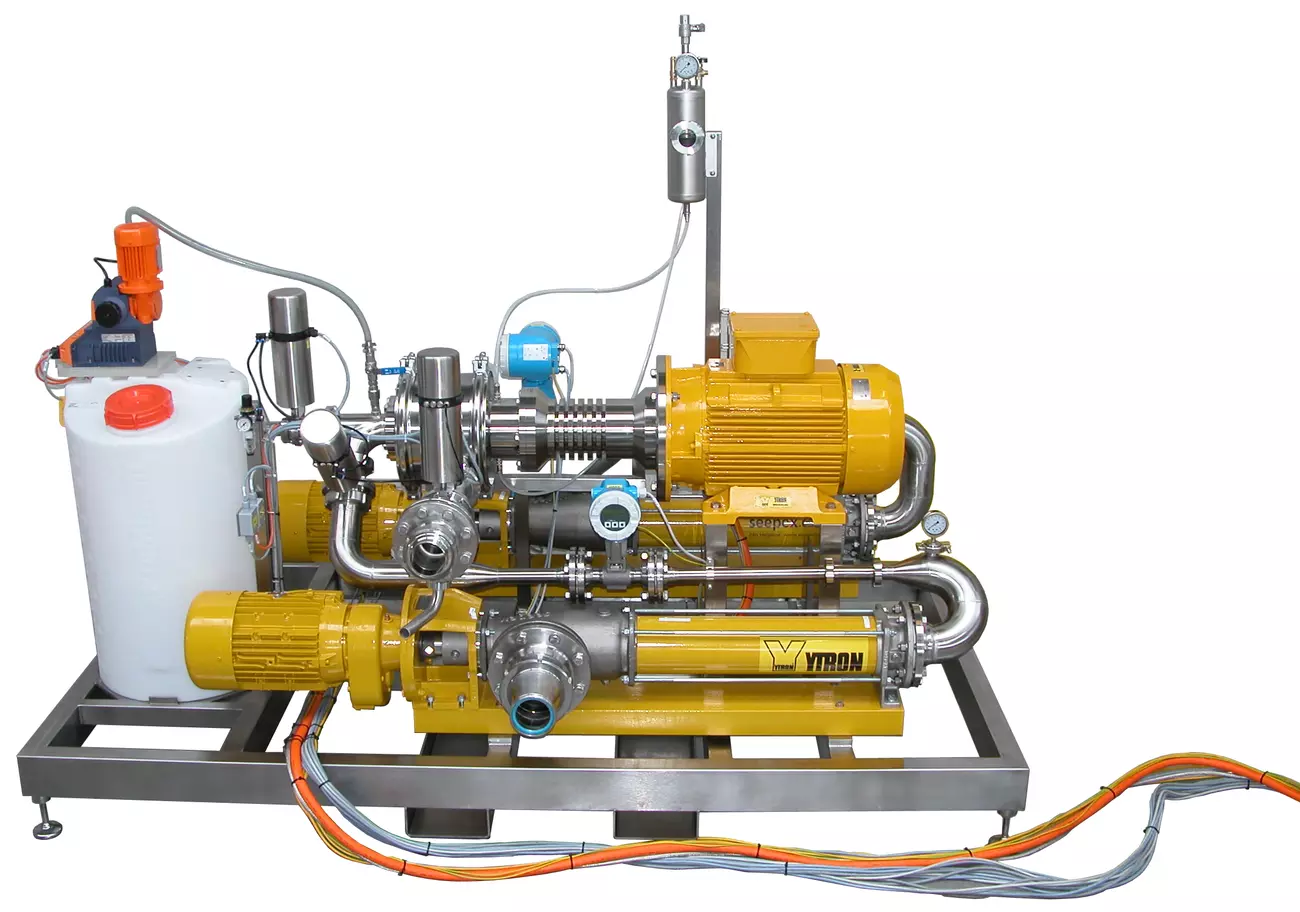

YTRON InLine Dilution System

Surfactants (e.g. sodium lauryl ether sulfate = SLES) are used in many cleaning products for personal and household use. As a rule, these raw materials are produced and transported in a highly concentrated, thick fluid form. However they require to be diluted before further processing can be carried out. In the case of SLES, a dilution from 70% down to a maximum of 28% is common.

A compact solution, offered by YTRON is a fully automatic dilution system based on the YTRON-Z inline homogeniser. In this process the surfactant and water are metered continuously in the required proportions and passed through the YTRON-Z to produce a lump-free diluted product. The raw material can be taken from a storage tank or directly from the road tanker and diluted for further use.

Specifications:

- Compact system including electrical cabinet with touch panel

- Capacity: 1,000 - 20,000 kg/h final product

- Selectable concentrations: 5 - 28% SLES

- Quantity measurement

- Volumetric dosing

- Optionally with preservative dosing

![[Translate to English:] Anlage zur Herstellung von Tabletten-Beschichtung (tablets coating)](/fileadmin/_processed_/3/0/csm_Mischtank_mit_Y_Bypass_11B030038_980c4c4fdc.webp)

YTRON-Y dispersing station

- Incorporation of lump-free powder which do not tend to stick in liquid template in a batch process

- Designed for ATEX applications

- System configuration according to customer specifications

YTRON-ZC 5 ViscoTron Powder Dispersing Plant suitable for ATEX operation

- Plant for suspending pigment powder in water

- YTRON-ZC 5 powder disperser

- Positive displacement pumps for feeding and product discharge

- Low-dust powder loading by the big bag emptying station

- Control system for semi-automatic operation

- Capacity: 30 big bags within 8 hours

- Viscosity of the pigment slurry: 10,000 cP

YTRON BigBag Dispersing Station

- BigBag station allows fast, lump-free powder incorporation in very short term.

- Perfect product quality.

- Low power consumption (only 7,5 kW up to 4 t/h powder injection)

Mixing tanks equipped with YTRON-Y

- Homogeneous and very quick mixing of liquids without air-entrainment

- Ideally suitable from water like viscosities up to more than 50.000 mPas

- No bearings and seals in the immersed section, therefore maintenance requirements are low

- Easy to clean

- Available for use in ATEX zones