Background / Application

- Shampoo is conventionally produced by using slow-speed agitators with multiple stage stirrer organs, because of the high viscosity.

- During filling of the production vessel, the liquid surface passes through the upper stirrer stages inevitably which leads to strong foam formation.

- This foam layer cannot be actively removed in atmospheric mixing vessels and thus remains stable for a long time.

- The results are long process times and reduced product quality.

The YTRON solution

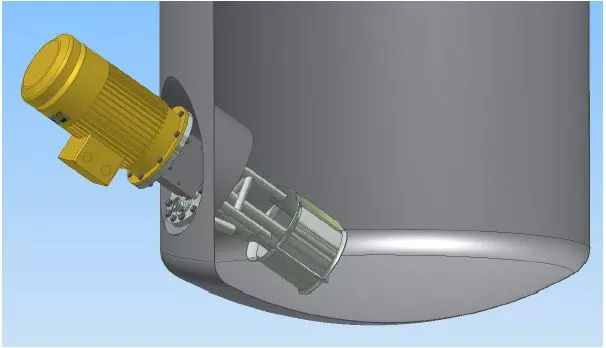

- An YTRON-Y jet mixer provides its optimum mixing performance, when installed with the mixing head near the tank bottom. There liquid surface does not touch the mixing head during mixing operation.

- The jet mixer avoids vortex formation by its fully axial jet stream.

- Therefore air entrainment and foam formation are minimized during when filling and emptying of the vessel container such as during mixing operation.

Advantages of the YTRON-Y Jet Mixer

- The YTRON-Y jet mixer guarantees a fast and homogeneous mixing of the vessel.

- The adjustment of the pH value and the subsequent mixing in of flavorings or colorings are possible within a very short time.

- The process times are considerably shorter in comparison with a propeller agitator.