Background/Application

High molecular weight polyacrylic acids, e.g. B. Carbopol® and other carbomers offer users in chemical, cosmetic or pharmaceutical companies a variety of interesting product properties.

These include efficient gel formation or thickening and stabilization of suspensions or emulsions. However, the incorporation of these substances on an industrial scale frequently causes problems for many users. The reason for this is that they immediately form a hydration shell when they come into contact with water.

The result is a grainy, unhomogeneous structure, which in some cases cannot be improved by prolonged swelling. A subsequent introduction of high shear forces often leads to the breaking of the polymer chains and a reduction in viscosity.

Product examples: Medical products (pain and wound gels, ultrasound gels, disinfectant gel), hair setting products, eye drops

The YTRON-Solution

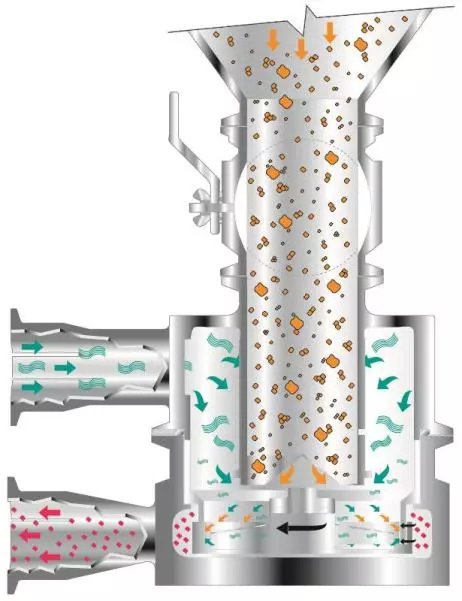

With the YTRON-ZC, the polymer particles are spontaneously broken down and wetted in a single pass. The special rotor-stator mechanics cause “stretching®” of the molecular chain and thereby achieve a significant increase in viscosity. Accordingly, material can be saved in the recipe. The negative pressure generated by the rotor/stator ensures an even powder supply and no secondary air is sucked in. Concentrations of up to 10% can be achieved. Preparing higher concentrations that can be diluted later saves significant time, energy and material in some applications.

Advantages of the YTRON

- Fast and efficient dispersion in a single pass

- Homogeneous product without lumps, agglomerates or "fish eyes"

- Highest viscosity yields through controlled shear

- Minimum dust generation when using a suction lance