Background / Application

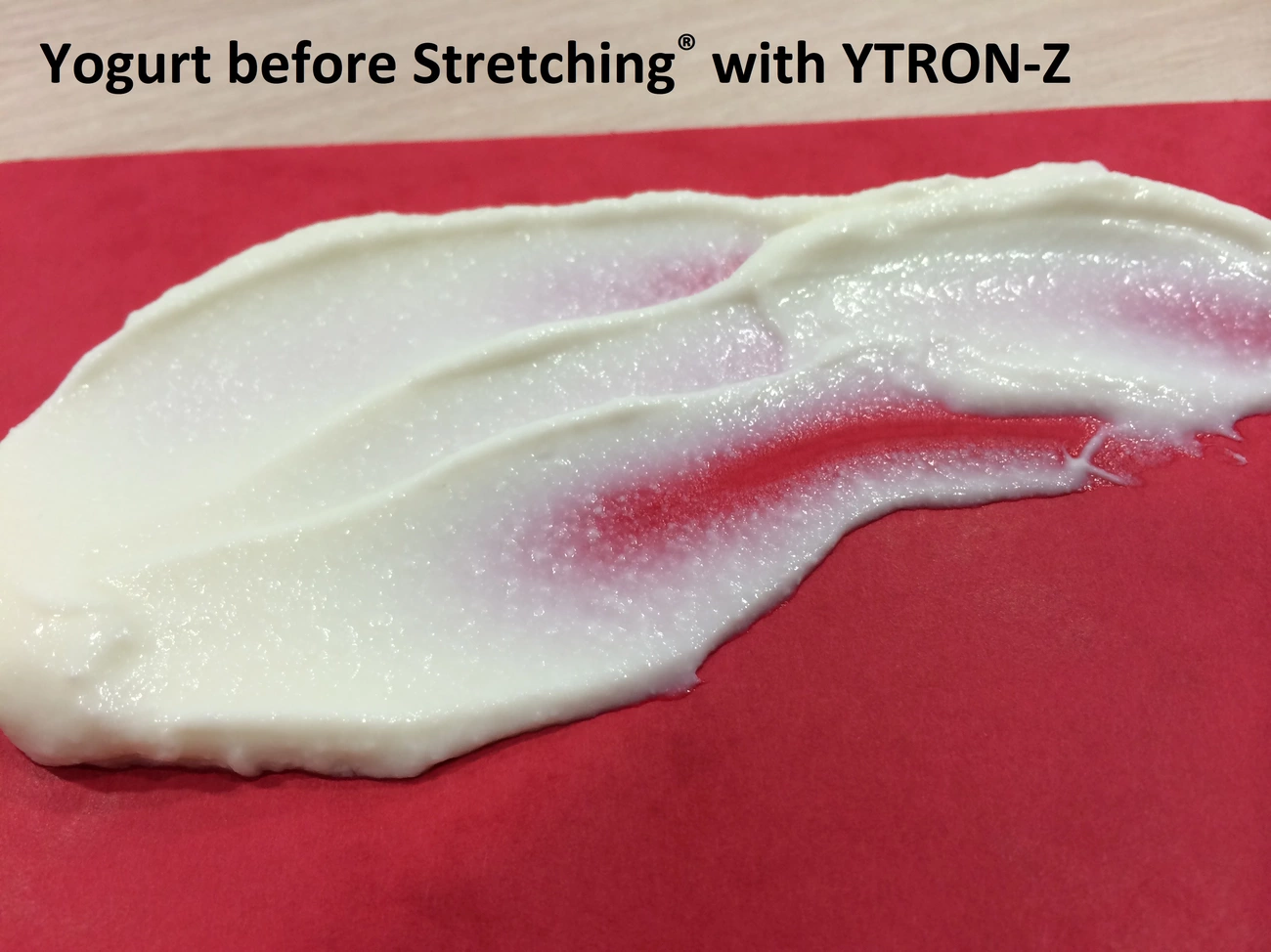

Various influences during production can lead to significant product quality fluctuations in cultured dairy products. Main reasons are temperature change, pH change and mechanical disruption. The result could be a “gritty” mouthfeel, syneresis and reduction or fluctuation in viscosity.

Original methods:

The previous method used to smooth the yoghurt was to stir the product in the incubation tanks once the correct pH value had been achieved. However, this could have an effect on the shear sensitive gel resulting in a reduction of viscosity. This method does not solve the problem of a “gritty” product. Stirring also causes air to be drawn in which in turn can cause “off -flavours”. Other methods used include “smoothing” or “structurising valves”. The grittiness of the product is reduced with this method. However, a negative side effect is a significant loss of viscosity and potentially still a gritty product due to pressure fluctuations towards the end of the process with some of the grits or nodules passing through the valve and ending up in the final product. In-line sieves or strainers are one of the other methods used. These give an acceptable result but product is retained in the filter resulting in a loss of viscosity and CIP does not lead to acceptable results.

The YTRON solution

Stretching® of cultured dairy products is the ideal method of reproducible processing with a defined introduction of shear using the specifically designed and geometrically optimised slotted rotor/stator system. The YTRON-Z can be fitted with a single, double or triple rotor/stator set each consisting of a pair of triple row shear tooling. With the parameters of slot width, number and distance of shear slots, number of rotor/stator sets, rotational speed and flowrate the desired shear effect can be reliably adjusted for all types of cultured milk products from low-fat yoghurt to fromage frais.

Advantages of the YTRON-Z Homogeniser

- Gel stability is improved and the consistency of the product resembles cottage cheese or quark

- Complete elimination of syneresis and grit or nodule formation and the product is smooth

- The protein content in the milk base can be reduced by 0.2%

- The end result is a full-bodied product with a rich, smooth mouthfeel.

![[Translate to english:] YTRON-Z 400 Homogenisator](/fileadmin/_processed_/1/0/csm_Z400_einstufig_Molkerei_899c7042cf.webp)